UI/UX

Nutrio is an AI-powered food product development platform designed for entrepreneurs, startups, and R&D professionals to ideate, formulate, and source ingredients seamlessly

Details

Project

Salesforce, Relationship Design Challenge ‘25 Submission (Finalist)

Role

Solo Product Designer

Duration

5 Days

How might we create an AI-powered virtual product development studio that enables brands to go from idea to validated formulation, without ever entering a physical lab?

Target Users

Nutrio is built for professionals involved in food product creation and innovation

• Solo Entrepreneurs – Individuals developing and testing new food ideas independently

• Startup Founders – Brand owners creating and scaling innovative food products

• Corporate R&D Professionals – Experts optimizing formulations and ensuring product compliance

Research

The goal of my research was to understand how food product development works, the challenges faced by food startups and R&D teams in bringing new products from idea to formulation, identify inefficiencies in the current process, and explore how AI could simplify and enhance different stages of product development

Market Research Insights

Key industry statistics highlighting the growing need for faster, data-driven, and cost-efficient food formulation and development solutions

Key Stages in Food Product Development

As my challenge focused on the Ideation and Formulation phase only, I conducted in-depth research to understand how these stages operate and where inefficiencies or gaps exist

Product Development Types

In the food industry, product development can be broadly classified into two key categories

1.New Product Development-

Involves creating a completely new product from concept to market launch — starting with idea generation, ingredient sourcing, lab formulation, testing, and scaling up for production and commercialisation

2. Line Extension-

Involves creating a completely new product from concept to market launch — starting with idea generation, ingredient sourcing, lab formulation, testing, and scaling up for production and commercialisation

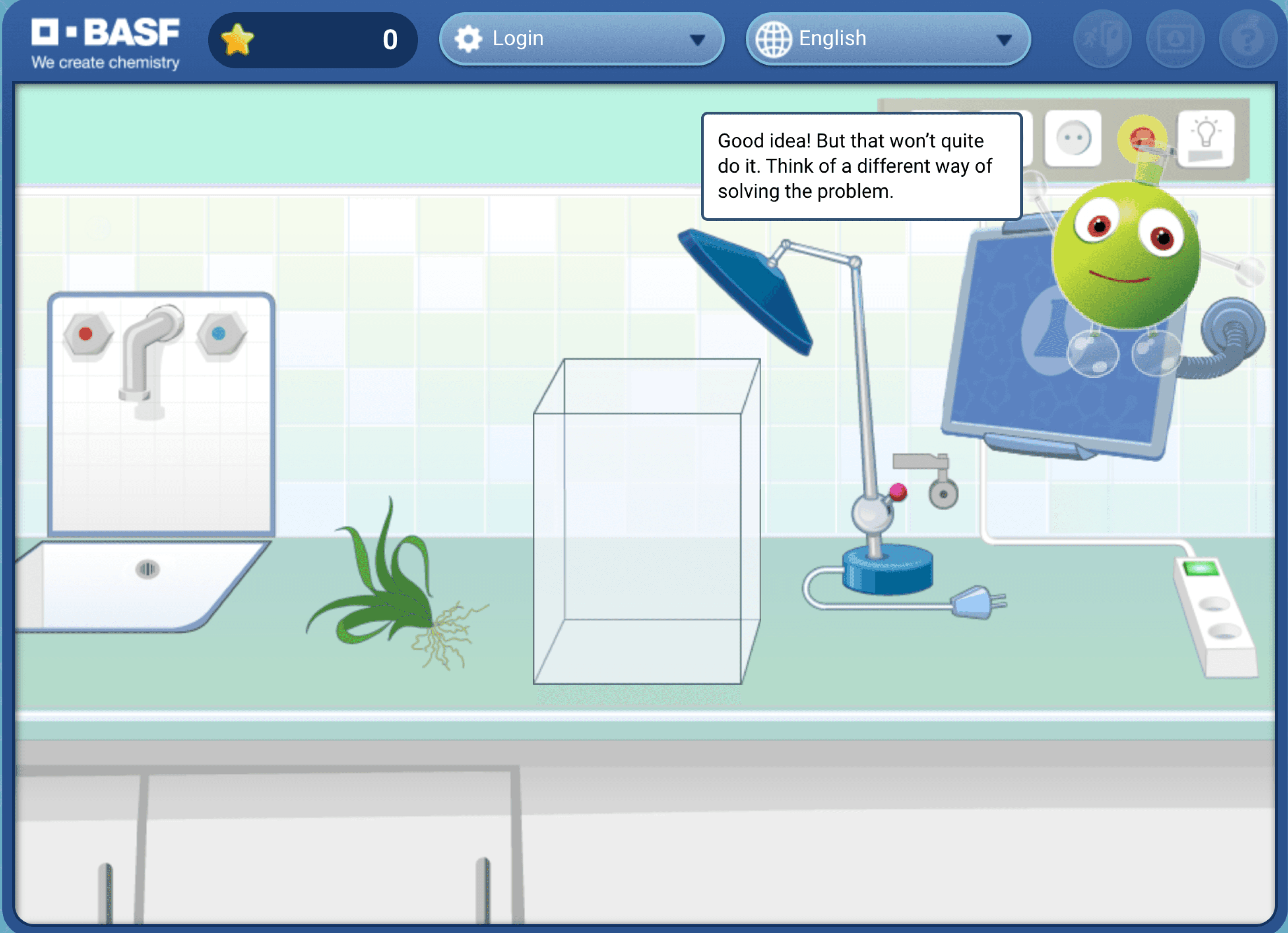

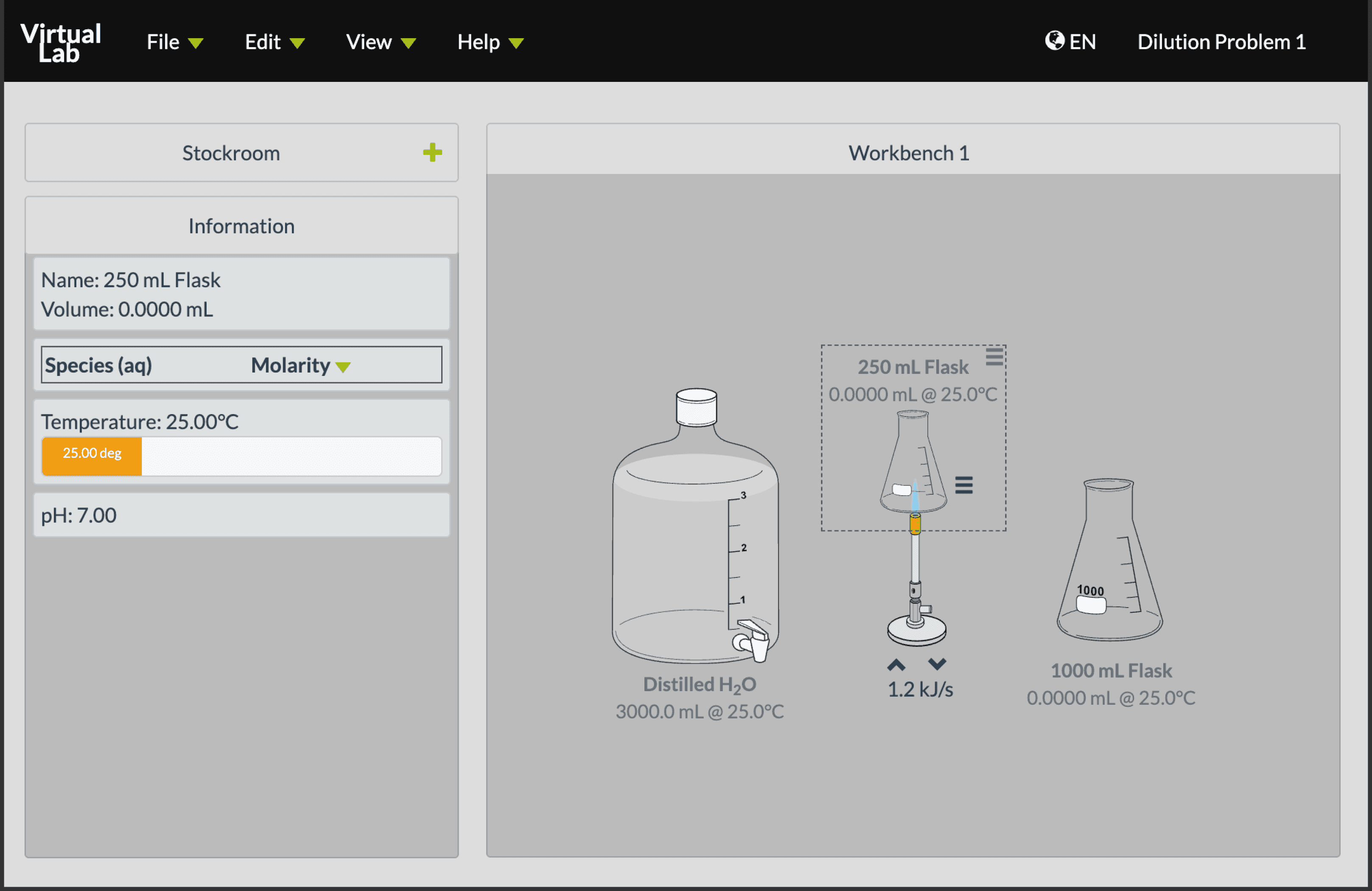

Virtual Lab Exploration

To understand how digital environments replicate real lab experiences, I explored platforms like ChemCollective and BASF Virtual Kids’ Lab

These tools helped me learn how virtual labs visualize experiments, provide real-time feedback, and guide users through complex procedures interactively

Projected growth of the Market for Food Processing Technology in India by 2024, showing strong industry investment in technological solutions

Source - IBEF

₹2.5L Crore

The projected growth rate of the Organic Food Market in India by 2025, driven by evolving consumer demand for specialised, healthy products, requiring faster and more precise R&D

Source - Indian Organic Market Report (2022)

20% CAGR

The cost range for the Recipe Formulation phase alone for a general food product, which typically requires multiple physical trials

Source - Foodsure (2025)

₹1.5 - 3.5L

1

Ideation

Generating product ideas based on market needs and trends

2

Formulation

Lab testing and ingredient selection to achieve taste, texture, and nutrition

3

Processing

Scaling the lab formulation for consistent large-scale production

4

Commercialisation

Finalizing packaging, compliance, sourcing, and market launch

3

4

2

1

Workspace area

Interactive centre aligned workspace area

Avatar

Avatar pops up to guide for next steps, but users can not interact with it

BASF Virtual Lab

Lab Equipments

Left aligned, collapsible workspace area, the items are fixed based on ongoing experiment

Workspace Area

User can drag equipments from left panel and can perform experiment in this area

Chemcollective

Virtual Lab

Current user flow

Understanding how food innovators currently move from idea to formulation, highlighting the inefficiencies and loops in the existing process

Idea Generation

Concept Definition

Ingredient Research /

Feasibility Check

Formulation Drafting

Lab Testing /

Prototype Trial

Preliminary Evaluation

Identifying Pain Points Across the User Journey

Understanding how food innovators currently move from idea to formulation, highlighting the inefficiencies and loops in the existing process

Ingredient Research / Feasibility Check

• No centralised database to compare ingredient availability, cost, or compliance

• Manual research consumes days, often resulting in incomplete or outdated data

Formulation Drafting

• Requires physical lab access and expert knowledge for accurate ratios.

• Difficult to understand how changing one ingredient affects nutrition, stability, or cost

• Limited visibility into alternative ingredients with similar functions

Lab Testing / Prototype Simulation

• Highly time-consuming and expensive (each trial costing ₹15,000–₹30,000)

• Multiple iterations needed before achieving desired taste or texture

• Lacks predictive tools to estimate shelf life or sensory profile digitally

Preliminary Evaluation (Cost, Nutrition, Compliance)

• Evaluations are done manually or using separate tools, breaking workflow continuity

• No real-time feedback; users only know results after full testing

• Compliance checks require regulatory expertise not accessible to startups

User Personas

I identified two key user types representing different goals — one focused on creating new products and another extending existing ones within established brands

Problems

• Limited access to R&D labs and formulation experts due to high cost

• Iteration cycles are slow — physical trials take weeks to test taste and stability

• Limited access to R&D labs and formulation experts due to high cost

• Limited access to R&D labs and formulation experts due to high cost

Goals

• Rapidly prototype and validate new product ideas digitally

• Compare formulation variations in real-time before physical testing

• Ensure compliance and nutrition balance early in the process

Pravin Sharma

29, Founder, YogCraft – a health food startup

Problems

• Reformulating the existing recipe to include probiotics changes the drink’s shelf stability and flavor balance

• Limited lab time and high trial costs make iterative testing difficult

• Difficulty in finding compliant probiotic ingredients that match brand flavor standards

Goals

• Digitally simulate how probiotic addition impacts taste, nutrition, and shelf life

• Maintain Paper Boat’s signature fruity taste while improving health perception

Nisha Kapoor

30, Senior R&D Technologist, Paper Boat

NUTRIO

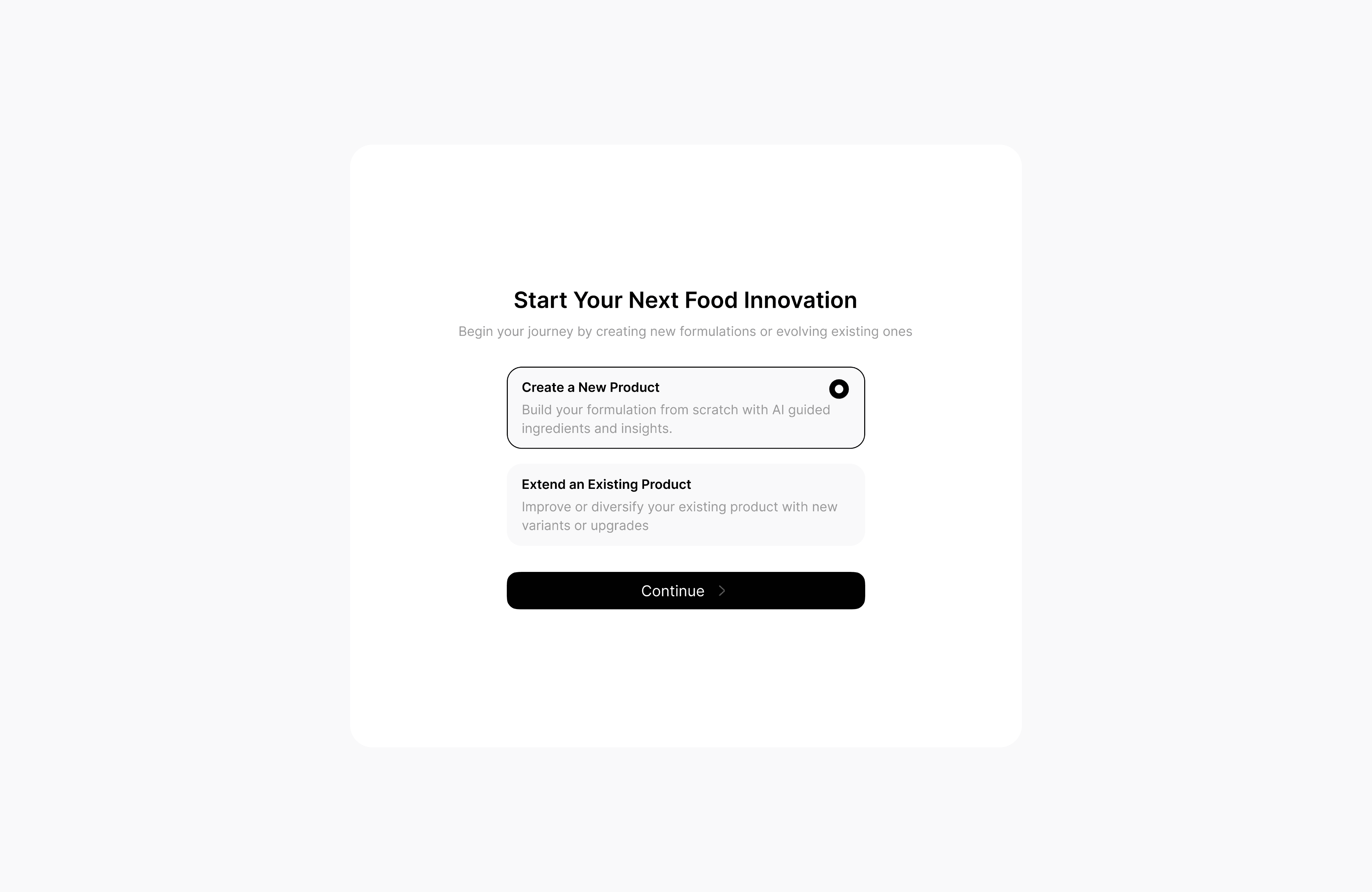

Choose product type

User will be given options, is it new product or line extension of existing product

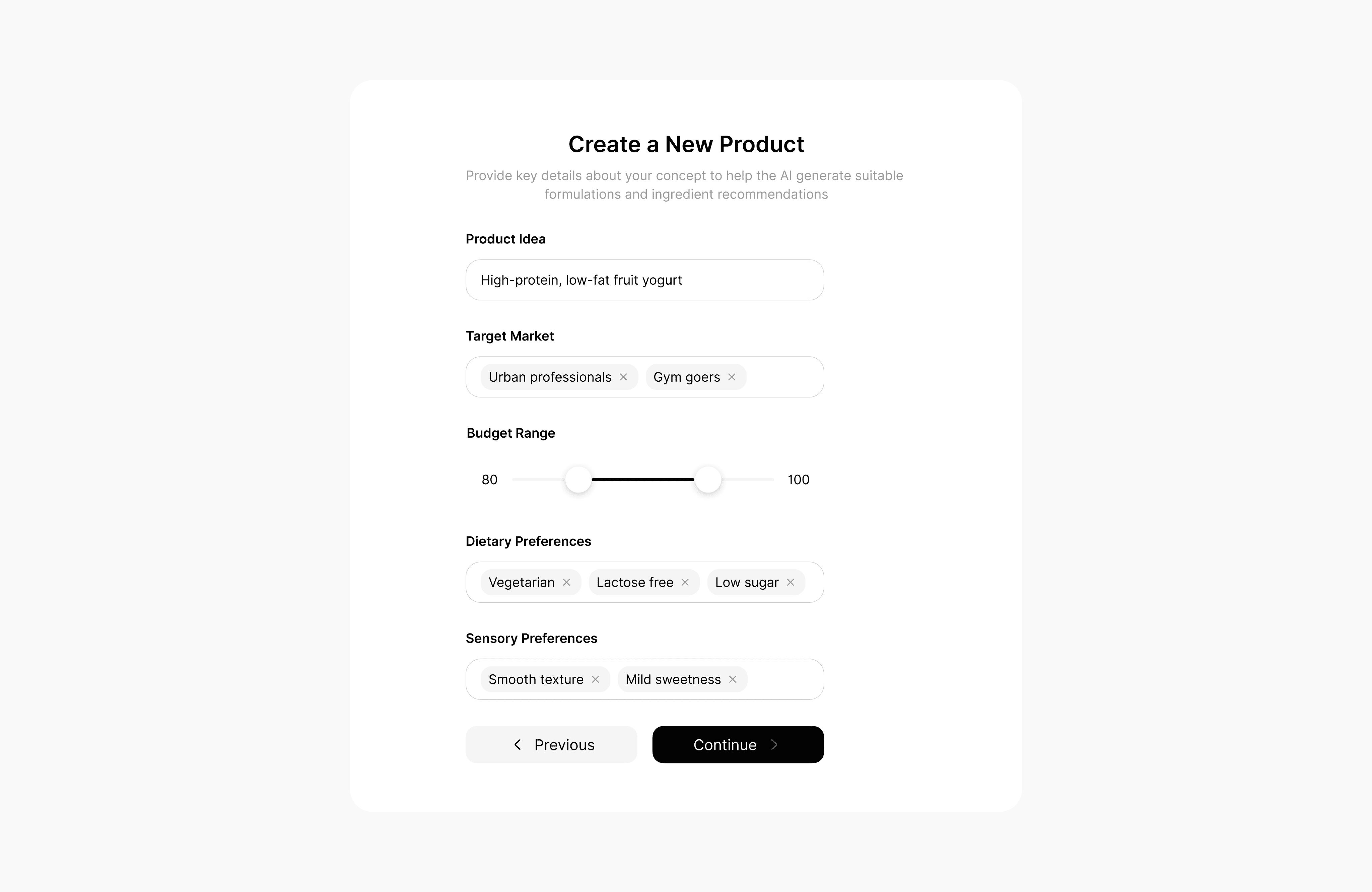

Creating a new product

The details collected at this stage are later used by the AI to generate insightful and feasible formulation suggestions.

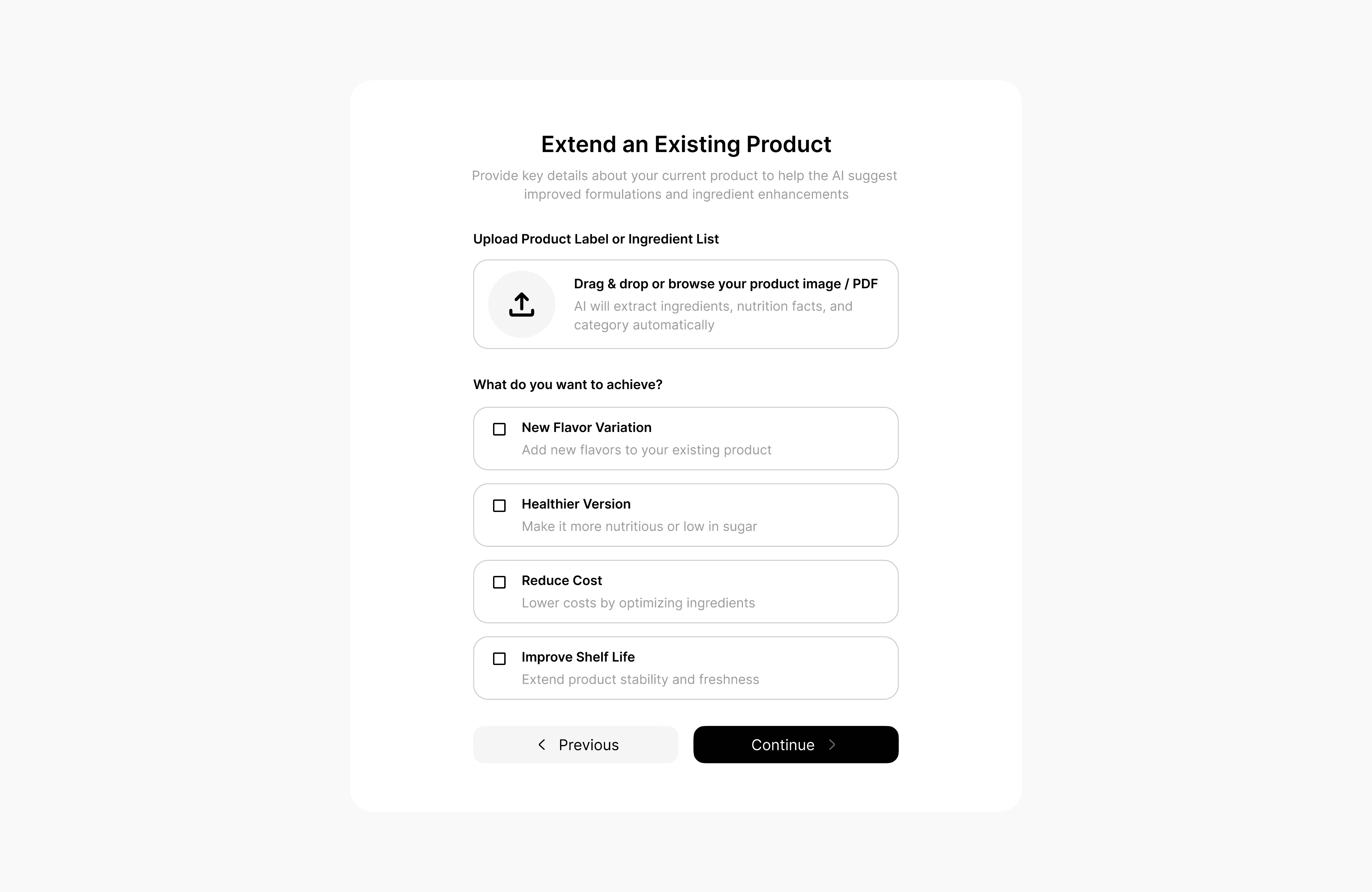

Line extention of product

Creating a new product

Ai will automatically extract ingredients, nutrition facts and category automatically

New user flow

This flow illustrates how Nutrio supports and enhances existing food R&D workflows by assisting users from feasibility to sourcing, helping them make faster, smarter, and more confident formulation decisions

Proposed Solution

A virtual platform that simplifies food product development by assisting users in formulation, evaluation, and ingredient sourcing through AI support

Idea Generation

Concept Definition

AI-Generated Ingredient Listing

Virtual Lab Simulation

AI Evaluation

Ingredient Sourcing

Ideation Phase

As stated in the problem statement, users enter the platform with a clearly defined product concept. Therefore, at this stage, I did not focus on providing insights or feedback on the idea itself, assuming it has already been thoughtfully developed by the user.

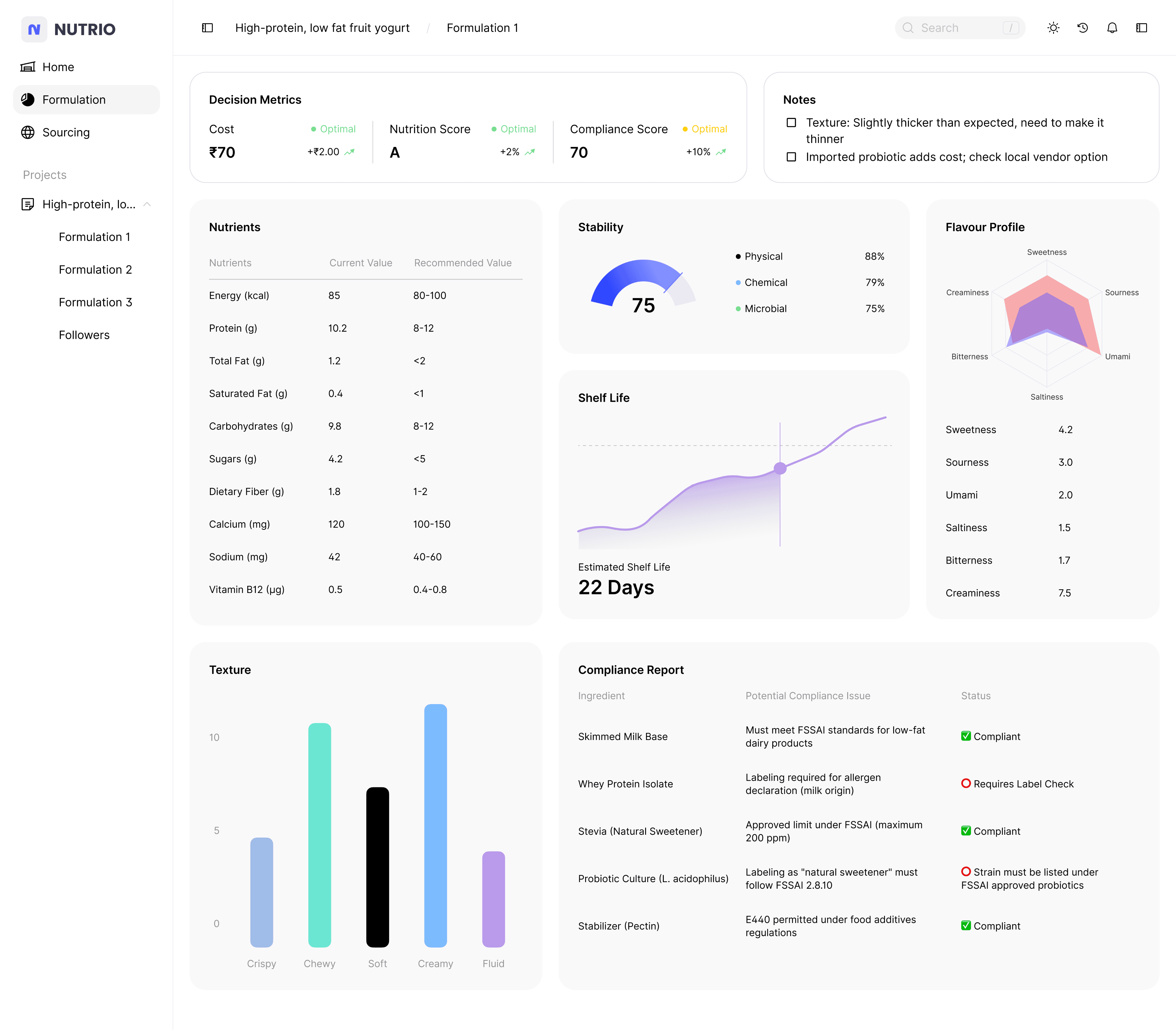

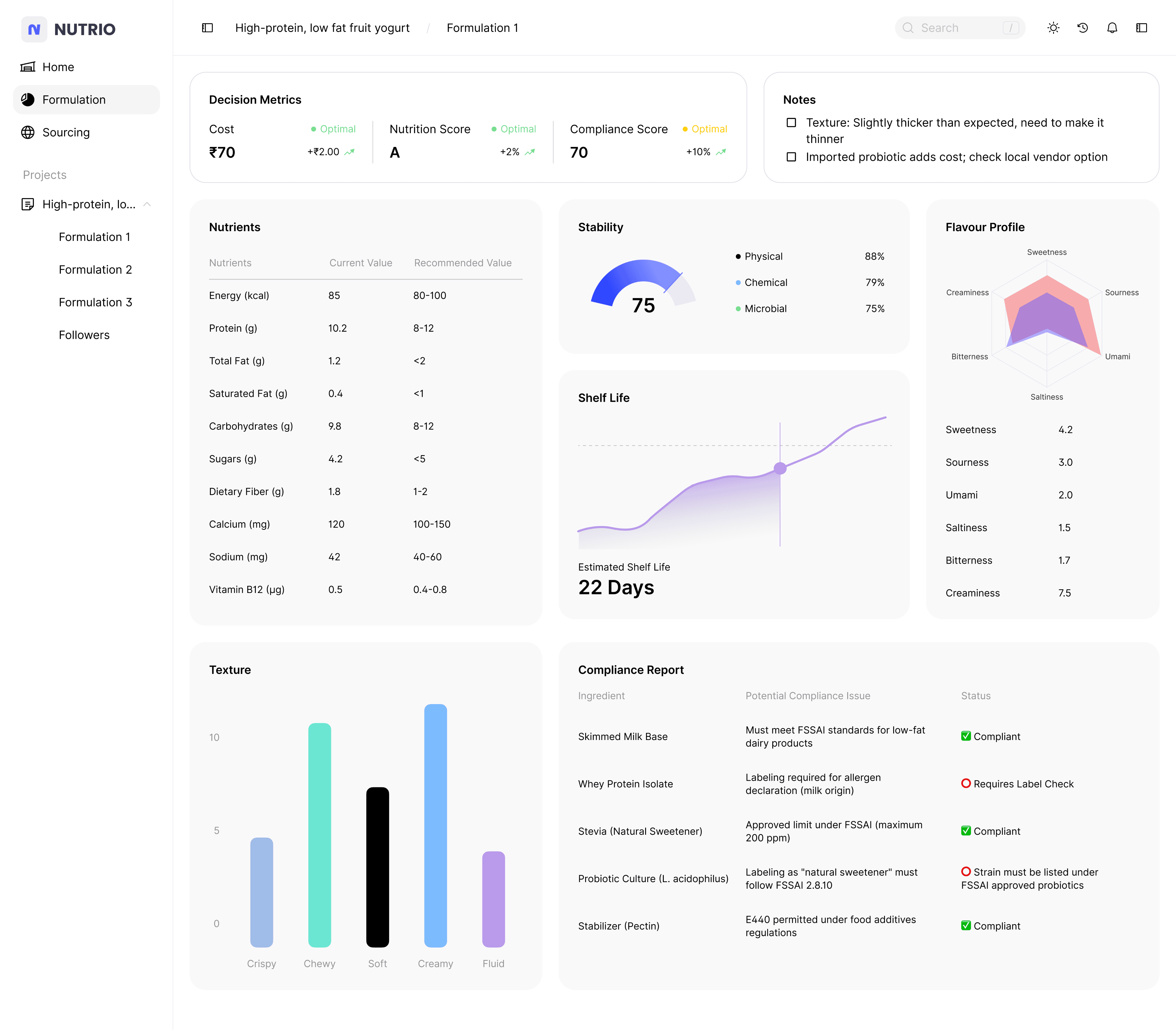

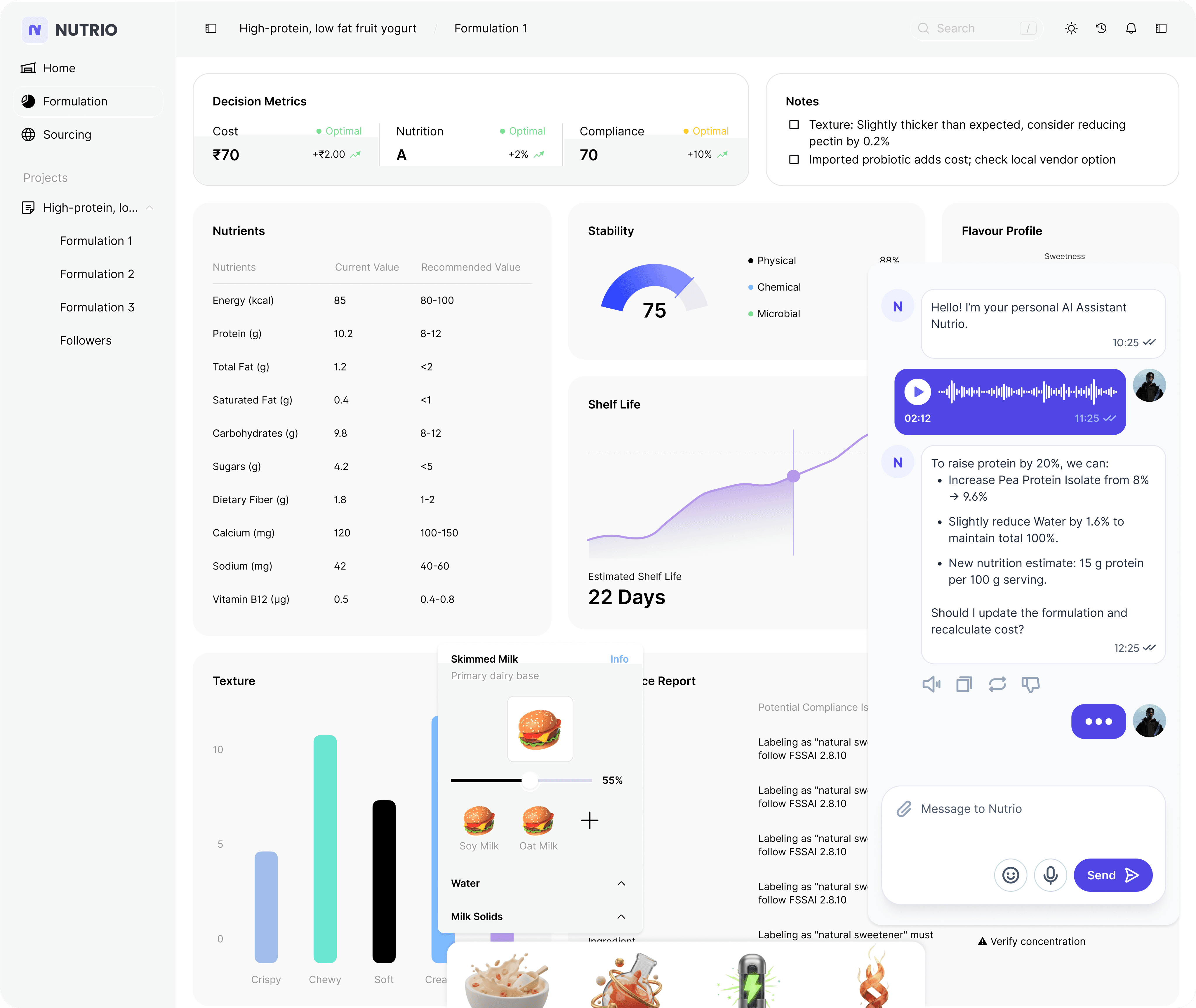

Decision Metrics & Notes

Ai will automatically extract ingredients, nutrition facts and category automatically

Product Performance Insights

Comprehensive AI-driven analysis showing how each formulation performs across nutrition, stability, and sensory attributes

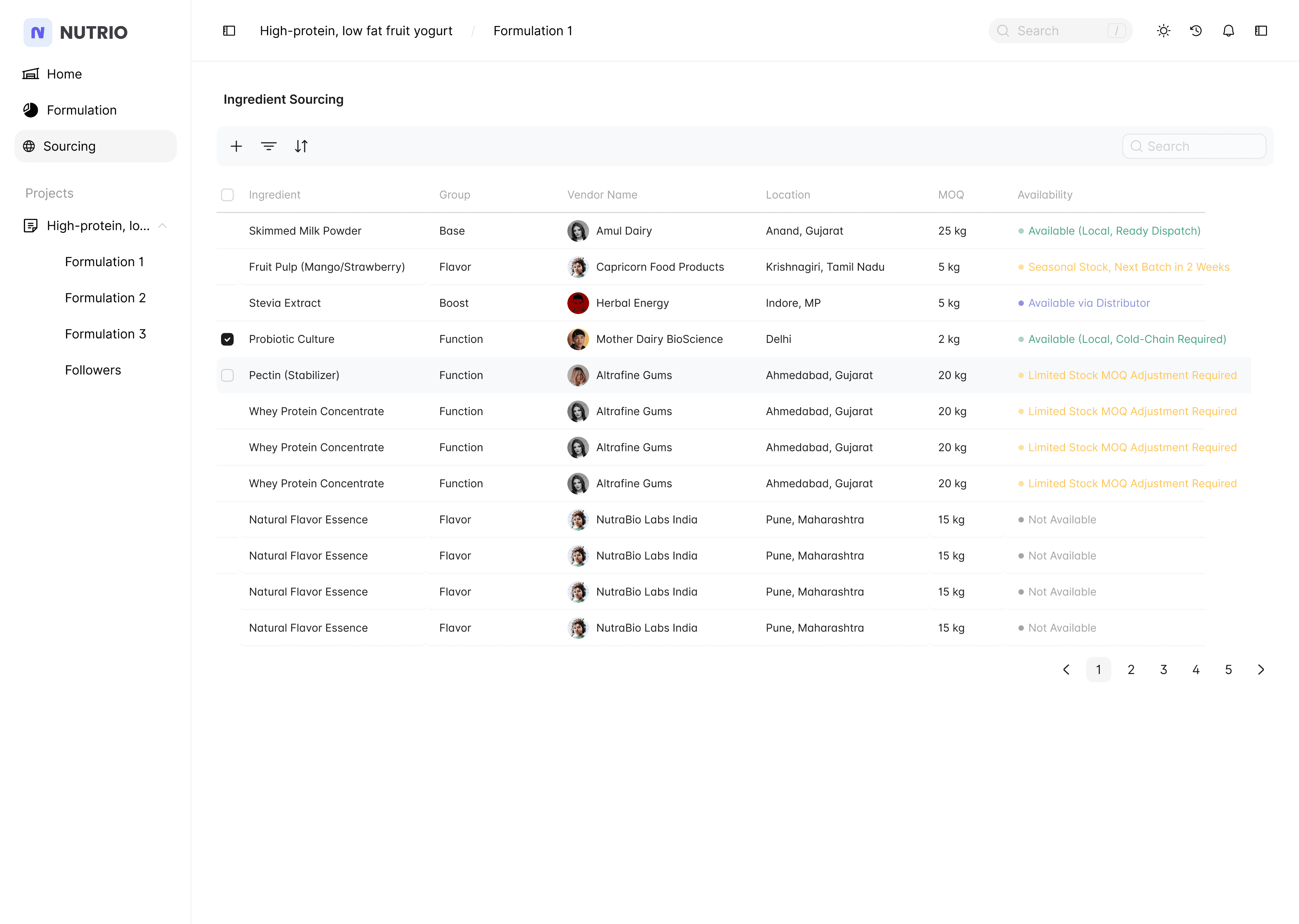

Formulation Workspace

Ingredient Sourcing

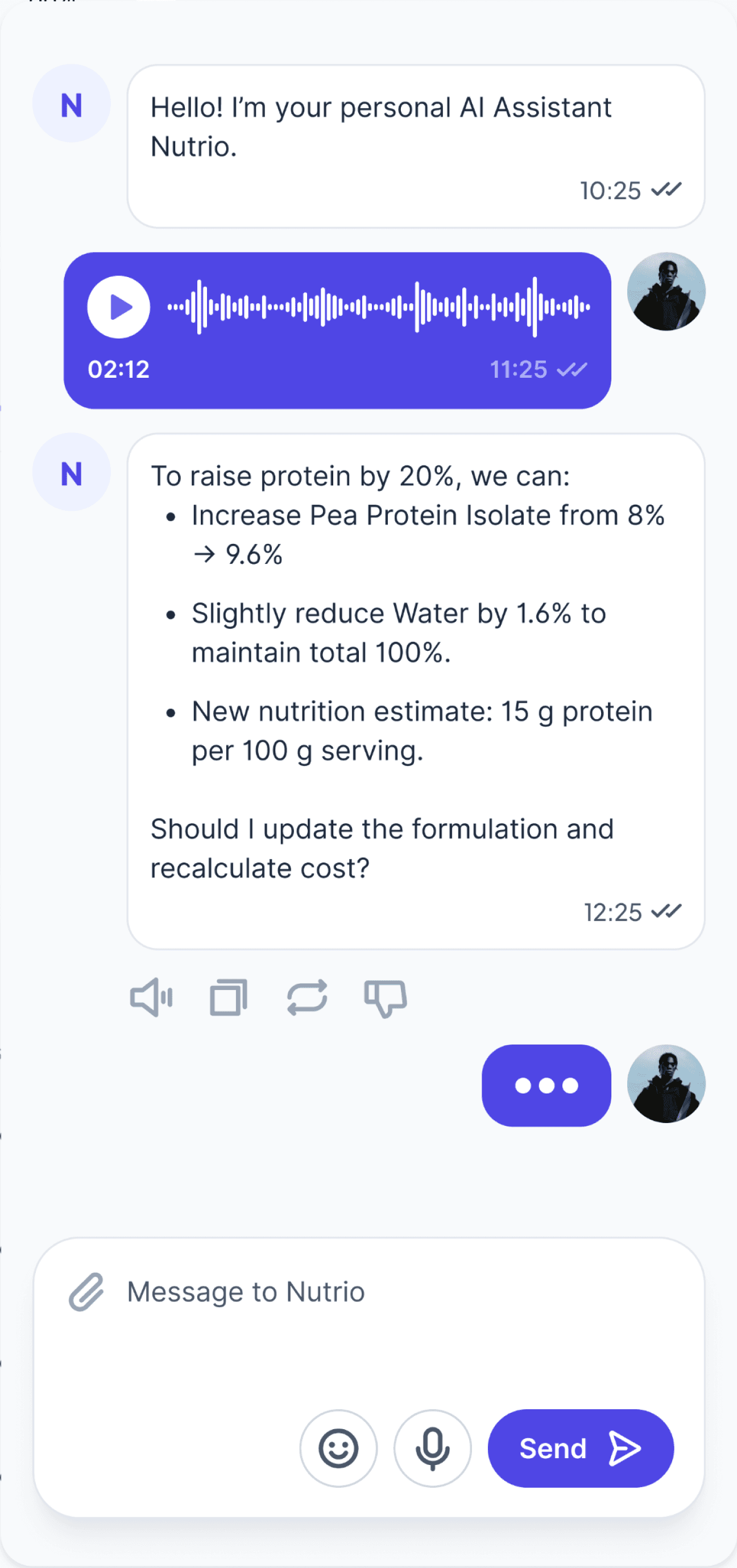

AI Chatbot

User will ask best next step to take in formulation, ask queries in text and audio format

Ingredients

Ingredients are auto-suggested based on the product concept, allowing users to make “what-if” adjustments and instantly see the impact on their formulation.

55%

Soy Milk

Oat Milk

Water

Milk Solids

Skimmed Milk

Info

Primary dairy base

Formulation Workspace

The core area of the platform where users experiment with ingredients, tweak formulations, and instantly see the impact on taste, nutrition, cost, and compliance — all through an interactive, AI-assisted dashboard

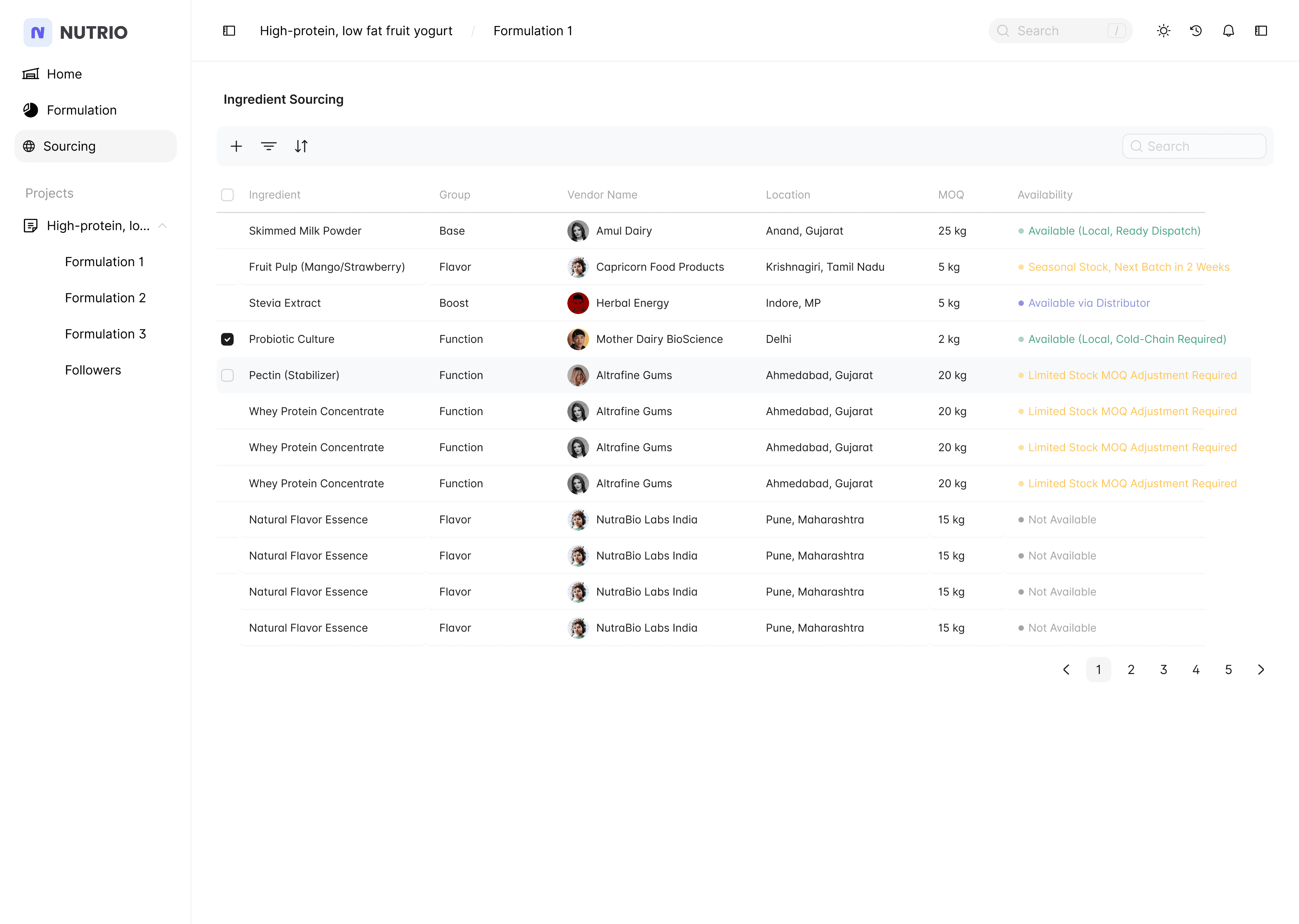

Ingredient Sourcing Page

A consolidated view where users can explore verified local vendors, compare ingredient availability and cost, and finalize sourcing decisions directly from the platform

Project Learnings

Got a deeper understanding of how food product development actually works — from ideation to formulation

Learned how formulations are created, tested, and refined based on taste, nutrition, and stability

Understood how AI can simplify complex formulation decisions and make R&D more accessible